Begin a conversation around building a home for a potential client, and one of the first questions will be, “How much will it cost?” Now is not the time to ask such a question as during the interview phase of talking to prospective builders. Costs will be approximate and not anything a builder can commit to this early on in the meeting.

A much more searching question to ask would be, “how can we work with you to minimize the cost of our home yet build to the standard we need?” Now we can begin a meaningful conversation. It is also a conversation that you need to have before drawing the plans begins. One of the first things we try to manage with a new client is “expectations.” In the enthusiasm of a land purchase, it is tempting to believe that all will fall into place with little extra effort. We all fall into this trap, perhaps exemplified by that initial question of, “how much will it cost to build?” and our more often pointed reply, “do you have a plan yet? Your Contractor can have a major influence on costs from day one if allowed the opportunity. You do not have to take my word for this.

Let us look at an example.

A 3500 square foot, five-bedroom home built for the short-term rental market. Priorities are:

- Robust & timely construction

- cost effective build

- five bedrooms [the “sweet spot” in rental desirability]

- pool

- cost-efficient operation

- eye-catching interior finishings

For this discussion, we will just focus on “cost-effective build.” New construction projects in Palmetto Bluff are not usually known for low price building projects. There are many reasons for this, and one is the cost of materials locally. Take, for example, framing lumber. This is a commodity. in the same way as oil or coffee beans are commodities. Prices are set and monitored by market indices. For several reasons, the current price of framing lumber is three times higher than it was in the middle of 2020 (see graph). Most houses in Palmetto Bluff are stick-built and use a great deal of framing lumber in their construction. The remedy for this is to remove framing lumber from your build. Some would say that’s not possible, so let’s explore exactly the way to achieve that.

Footings

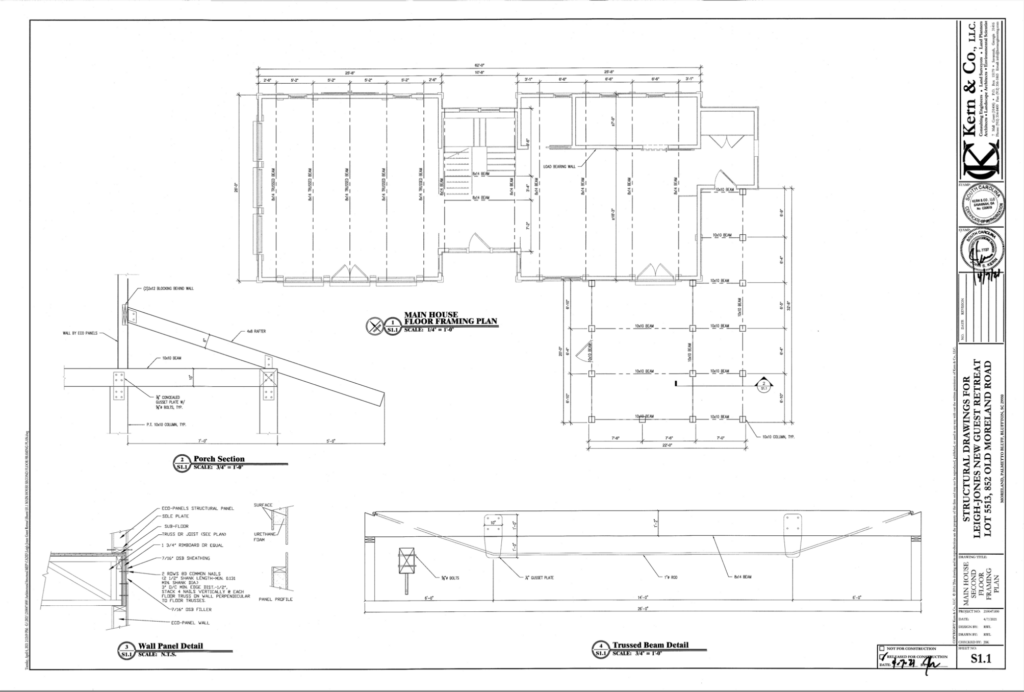

Pad the footings with either a stem wall or turndown on the edges. Blockwork for the stem wall as the elevation increases, backfilled, and then a 4 or 6 inches reinforced pad laid on top. You have removed framing lumber from the floors.

Walls

We often build using SIPS, Structurally Insulated Panel Systems (see example at 454 Old Landing Road, Palmetto Bluff). This is our preferred building material, and the reasons why are numerous. These are manufactured as a “sandwich” of OSB Board and expanded Urethane foam. The only studs used are for nail backers where hurricane strapping lands and around openings. They do not use framing lumber. On top of that, you get a Miami Dade County wind resistance rating at 150mph (local Code is 130 mph) and about three times Code (R40) for the insulation standard of the walls in a very air-tight build. Did I mention the fast build process? – you get that too. You have removed framing lumber from the external walls.

Flooring Systems

We have developed a flooring system that uses widely spaces structural timbers and a 3-inch tong and groove subfloor. In this process, we have removed all framing lumber from the floor system and replaced it with structural lumber that does not follow the same commodity price index. We have removed sheetrock from the ceiling and lay flooring grade planks on top of the subfloor above. We could drop the overall building height by about 12 inches, also saving on wall construction. Now you have removed framing lumber from the floors.

Roof

Not to labor a point, but SIPS again on top of structural rafters set at 48″ on center. Quite a neat system, and it has passed out structural calculations with flying colors: the roof, insulation, vapor barrier in one. No additional OSB sheeting over the top, and you have removed all framing lumber from the roof.

The above examples are for a single home. Some elements can be easily ported to other designs, some less so. However, by starting at the design phase and being imaginative on how the build will progress, we have managed to nearly eliminate one of the most expensive cost items in today’s build projects. Now you have a home with no framing lumber.

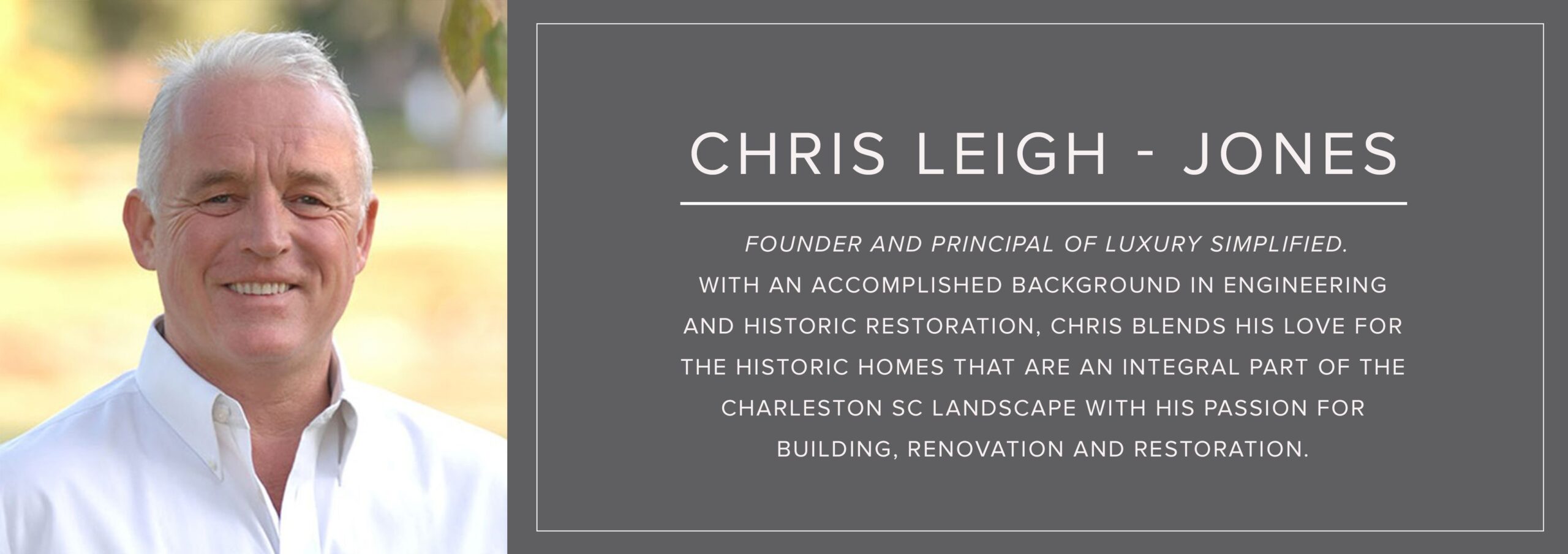

Building custom homes in Palmetto Bluff is not difficult if you understand the process. Our firm, Simplified Construction, has been awarded the highest approval category for building locally within the Palmetto Bluff development, providing our clients with the reassurance that we are indeed experts at the intricacies and regulatory demands of the design-build process. If you consider building your own home, let us work with you to make it happen quickly and cost-effectively.

Follow this blog series:

Building in Palmetto Bluff: Applying New FEMA Flood Requirements to Design

Palmetto Bluff: 4 New Builds Begin & Modern-Style Barn Design

Palmetto Bluff: Cost Estimations as a New Investment Project Begins